Introduction:

In a world grappling with climate change and the pressures of an ever-growing population, our approach to water demands a complete transformation. The days of a wasteful, “use once and discard” mindset must end as global water scarcity intensifies. Our future relies on innovative strategies to maximise every drop of water. Amid this need, grey water emerges as a beacon of hope—an opportunity to conserve fresh water through resourceful reuse. Grey water, consisting of the gently used water from showers, sinks, and washing machines, is often funnelled down the drain, disregarded as waste. However, treating and reusing grey water offers a sustainable oasis amid increasing water scarcity.

Adopting grey water reuse for applications such as irrigation, toilet flushing, and more goes beyond practicality; it signifies a shift in our relationship with water. It’s about closing the loop and transforming our homes and buildings into miniature ecosystems of conservation and resourcefulness. Effective treatment of grey water, involving a combination of physical and chemical processes, enables us to redefine water’s journey and purpose in our lives.

Greywater treatment typically involves techniques like screening, sedimentation, chemical processes (coagulation and flocculation), moving bed biofilm reactor (MBBR) technology, and sequencing batch reactor (SBR) processes, followed by settling, filtration, and ultrafiltration. Among these, coagulation-flocculation stands out as a critical step for sewage and grey water treatment, removing impurities and preparing water for further stages of purification.

VYTAL: Grasim industries’ innovative approach to grey water treatment

Grasim Industries is emerging as a leading supplier of water treatment chemicals under its “VYTAL” brand, dedicated to providing effective solutions to various industries. In this case study, we explore the efficacy of Vytal 710 and 610, specially formulated composite coagulants designed for grey water treatment.

In a real-world application, approximately 135 cubic meters of grey water is treated daily at the sewage treatment plant of Raheja Vivarea, Tower E, in Mahalaxmi, Mumbai. The treatment process involves multiple stages, as shown in Figure 1, including disinfection with sodium hypochlorite prior to ultrafiltration. The resulting treated water is repurposed for plantation irrigation, car washing, and other non-potable uses, demonstrating a practical solution to urban water management.

Problem statement:

The current treatment scheme is proving ineffective due to contaminants such as paint derivatives, cement, plaster of Paris (PoP), and asbestos, which hinder the performance of the MBBR and downstream systems. These impurities result in discolouration of the treated water, rendering it unsuitable for further applications.

Objective:

To reduce colour, cement, PoP, and asbestosis impurities before MBBR treatment. Characterisation of sewage water collected from a sewage treatment plant and tested for different parameters as shown in below Table 1.

| Sr. No. | Parameters | Remark |

| 1 | pH | 7.9 |

| 2 | Turbidity, NTU | 179 |

| 3 | Total Organic Carbon (TOC), ppm | 62 |

| 4 | Total Dissolved Solids, ppm | 276 |

| 5 | Chemical Oxygen Demand, ppm | 200 |

| 6 | Color APHA | 312 |

Table 1: Characterization of Sewage Water

Material and method:

Vytal 710 and 610 are designed based on hypotheses. The product is used for chemical treatment, i.e., coagulation and flocculation. It has a synergistic impact when used with secondary and tertiary treatment and helps to reduce the overall operating cost of treatment of effluent as compared to secondary and tertiary treatment. This product can be used as such or diluted. A jar test was conducted on site for selection and optimisation of the right product. Jar test conditions were taken as per Table 2. Based on the different trials, speciality solution Vytal 710, 610 (as coagulant) followed by Vytal 971 (as flocculent) developed for effective removal of suspended solids, separation of paint, and other impurities.

Results and discussion:

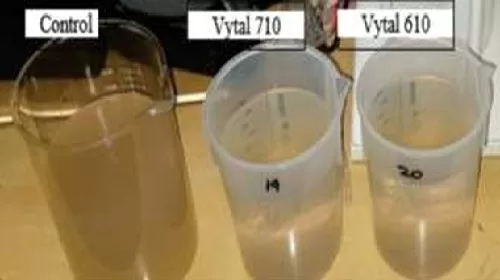

Dosage of Vytal 710 and Vytal 610 optimised using jar test to get the best result in terms of reduction in turbidity, colour, COD, and TOC as shown in Table 3 and Figure 2.

| Stage | Process | Speed (rpm) | Minutes |

| 1 | Rapid Mixing | 200 | 2 |

| 2 | Slow Mixing (Flocculation) | 40 | 4 |

| 3 | Sedimentation | 0 | 20 |

Table 2: Jar Test Condition

| Sample | Dosage ppm | Vytal A-971 | Turbidity | pH | COD (ppm) | TDS (ppm) | TOC (ppm) |

| Inlet | – | – | 179 NTU | 7.90 | 200 | 276 | 61.86 |

| Vytal 610 | 150 | 1 ppm | 5.0 NTU | 7.30 | 56 | 298 | 24.59 |

| Vytal 710 | 100 | 1 ppm | 7.0 NTU | 7.40 | 56 | 267 | 23.49 |

Table 3: Jar Test Results

Conclusion:

The Grasim dual-chemical system, utilising Vytal 710, Vytal 610, and A 971, proved highly effective in treating grey water effluent. Key achievements included over 95% reduction in turbidity and more than 70% reduction in COD, with minimal impact on pH levels. The system also demonstrated operational ease and enhanced performance of downstream processes, including MBBR, pressure sand filtration, carbon filtration, and ultrafiltration, making it a robust and efficient solution for grey water treatment.